Multi-PCB Assembly

Cryo-refrigeration Industry

Project description:

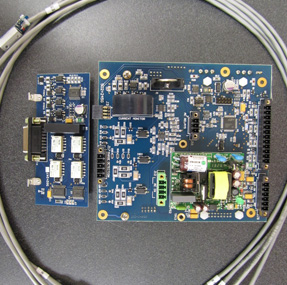

At Elmgrove Technologies, we provide PCBs and complex assemblies for customers in a broad range of industries. In this project, we helped a cryo-refrigeration industry customer with the manufacturing of five separate assemblies consisting of 1200 finished units. Known as the “245 Project,” it highlights our ability to deliver a diverse array of manufacturing services, both economically and with unmatched quality and consistency.

The PCBs consisted of mixed technology boards, which were composed of a RoHS-compliant FR4 material and assembled with SMT and TH technology with hand and automated processes. This was all provided in-house, including potting and encapsulation. Through our strategic partners, we sourced precision machining of custom heat sinks and stand-offs, as well as fully-assembled wiring harnesses.

While two of the assemblies were standalone units, others in the group were mounted together using connectors and PEMs, forming a single functional unit. One of the assemblies consisted of 4 smaller boards mounted to a custom machined aluminum block and wired to a cable connector. Each unit was assembled with stringent quality control procedures, using J-STD-001 assembly and IPC-A-610 Class II inspection standards.

Not only was our customer extremely pleased with the results, but we were able to perform a large volume of electromechanical services, custom production runs, and on-time delivery for a project of this complexity, all with a 120 day turnaround time. For more information on our work with multiple PCB assemblies, please contact us or refer to the table below.

Project Gallery

- PCB Assembly & Enclosure

- Multi-PCB/Cable Assembly

- PCB Repair & Rework

- Through-Hole to Surface Mount Conversion

Multi-PCB Fabrication Project Details

- Project Name

- 245 Project

- Project Description

- 5 different assemblies –

- PCBs consisted of mixed technology boards

- RoHS compliant FR4 material

- Assembled with SMT & TH technology

- Capabilities Applied/Processes

- Fabrication

Assembly

- Equipment Used to Manufacture Part

- Mixed Technology, TH and SMT, hand and automated processes, custom machined heatsinks and standoffs, wiring and cable assembly, potting and encapsulation.

- Overall Part Dimensions

- Material Thickness: 0.062

Product Length: 5.0

Product Width: 6.0

- Material Used

- RoHS FR4

- Material Finish

- ENIG

- Industry for Use

- Cryogenics/Cryo-refrigeration , Liquid Helium/Nitrogen Management

- Volume

- 1200

- Delivery/Turnaround Time

- 120 days

- Standards Met

- Assembled to J-STD-001 and inspected to IPC-A-610 Class II. Cables built to IPC-A-620 standards.

Printable Page

Printable Page  Email This Page

Email This Page